This morning, 3Km from home and a loud bang and the LHS suspension collapsed. I could guess the sort of trouble, stripped Tie rod end or snapped tie rod. Anyway, was able to drive home slowly with a severe list to port.

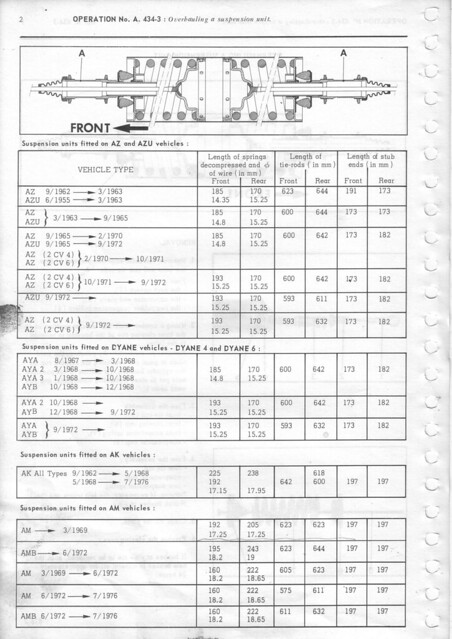

An hour later, suspension pot removed and the rear tie rod dropped out as the "mushroom" inside the spring canister on the end of the tiered had dropped off. Not quite what I expected of a complete suspension unit that was only 8 years old and on a road going car. Being of French supply (MCD) I would not even bother asking why this should happen, just hope the "Good" end is OK. Perhaps crack test it before re-assembly??

I have a couple of spare rods off the ancient suspension that may do the trick, one long and one short. Next weeks job is to grind off the end of the spring canister, clean it out and put it all back together again.

Are there any special tips I should look out for ??

BobH

|

Front spring or rear spring? by slcchassis, on Flickr

Front spring or rear spring? by slcchassis, on Flickr