| Author |

Message |

|

dave 411

Firing on two.

Joined: August 19th, 2010, 10:44 pm

Posts: 1815

Location: Cardiff

|

Re: Dave 411's 1967 AK350. Sam,the heads I am using have no valve stem seals either.The exhaust valve isnt dished,itsflat,but the new inlet valves,which have the later type split collets,has an indentation in it (see pics).

They are strange looking cam followers.Never seen anything like them before.Mine are like the ones on the left.

_________________

[img]http://i1207.photobucket.com/albums/bb480/alastairsmith999/dave411-5.png[/im

g]Horizontally Opposed

|

| February 24th, 2012, 9:29 am |

|

|

|

dave 411

Firing on two.

Joined: August 19th, 2010, 10:44 pm

Posts: 1815

Location: Cardiff

|

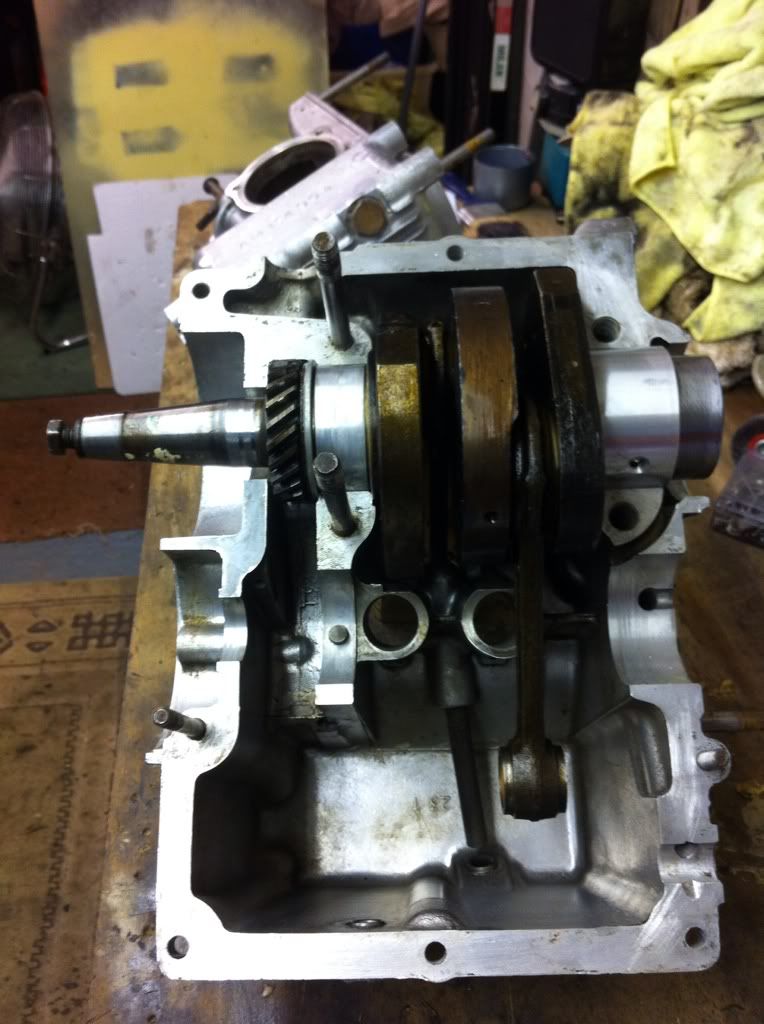

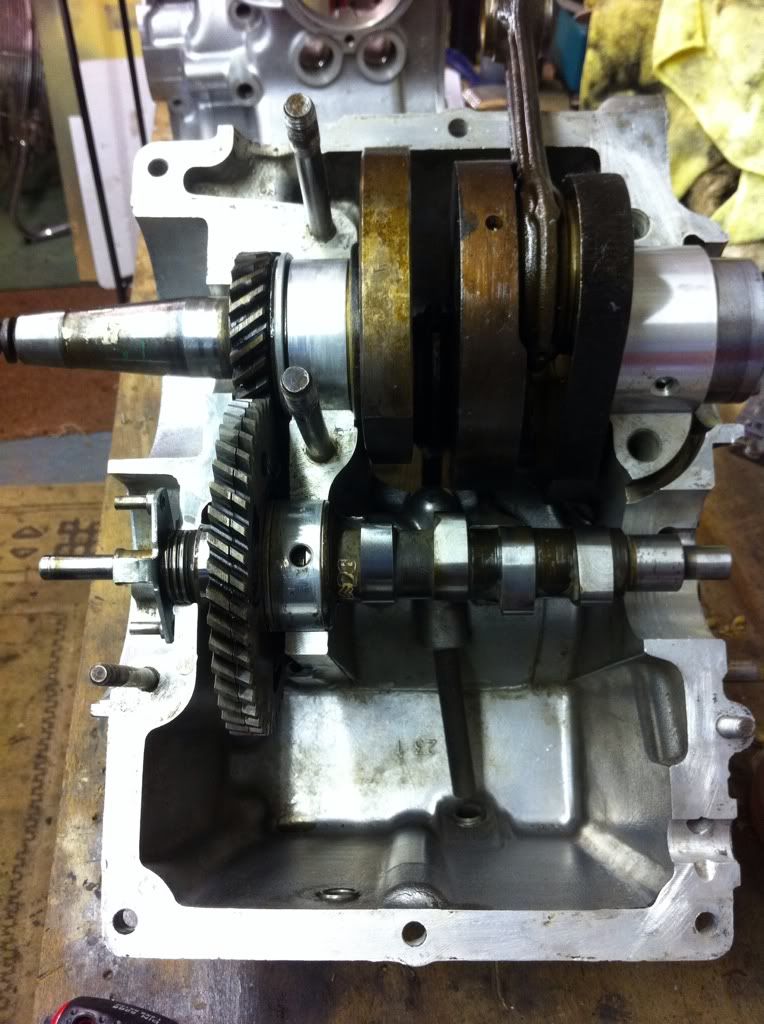

Re: Dave 411's 1967 AK350. Right then,after making sure the crankcases were clean,  time to drop the crank in,making sure that the main bearings,front and rear,were lined up with their dowels.A fiddly job,made harder because of the oil every where. Oh,forgot to mention,when rebuilding any engine,gearbox,carb,cleanliness is king.Make sure you clean everything to make sure theres no grit,dust,muck,old shoes,biscuits etc etc in what ever your rebuilding.I always use carb cleaner to blast everything,then copious amounts of oil to lube up.Apply/squirt oil into all the oil feed holes and journals in the crank and crankcase before dropping the crank in.  Next,the camshaft.Align the marks on the crank and cam,as per pic.   Next,the oil pump and oil strainer,    and then the crank seals,well greased,and the correct way around.   I now apply a crankcase sealer that we use on outboards,applied to one side and around the oil pump.If you ever re build an engine,NEVER EVER use silicone.Its not for engines,its for bathrooms.I have seen so many outboards writen off because someone has used silicone to seal the valve covers,then when the cover goes on the silicone squeezes out,on the out side,and the inside.Yes,it will seal it,but when it comes in contact with oil,it comes off said cover,goes into the sump and blocks the oil strainer,goodbye engine:eek:  Now carefully drop the other crankcase onto the sealed half and gently press them together.Now time to bolt it all together.Remeber to torque all the bolts,nuts as per the mannual,and this chappy,  goes in here(or at least,thats were it came from)  It has a shoulder on it so I think it must line up the crankcase? as there are no real dowels anywhere on either halves,Strange:confused:. So,all torqued up and ready for the pistons. One thing I forgot to mention,before tightening the bolts on the crankcase,make sure the oil seals are in squarely and just slightly behind the chamfer on the crankcase.It tells you in the mannual if in doubt.  Now lube up the cam followers and the hole they go into,making sure they go back where they came from,ie,into the same hole they came out of.    Next job was to fit the pistons to the conrods.Difficult to take pictures due to the fact that it is a two handed job and loads of oil on my hands,so I just fitted them,sorry.Basically,after making sure the piston is on the correct side,they are marked with a G and a D,G being gauche,left and D being droit,right,and the arrows pointing towards the front(exhaust) of the engine,the piston(gudgeon,wrist)pin is oiled and pushed into the piston until it just comes out of the shoulder inside the piston.Now offer it up to the con rod and align it up with the small end.Gently push the pin into the rod end and straight into the other half of the piston.Now fit one of the circlips into its groove inside the hole the pin is in.Once thats in,continue to push the pin in until it just touches the circlip.Now fit the other clip.making sure that both clips are in their grooves securely.Double check this,as we dont want the pin coming out and running a nice big groove down the cylinder wall:eek:.   Now the fiddly bit,fitting the barrels over the pistons.Use a piston ring compressor if you can.Again,no pics on this as its a fiddly job and I was on my own.Make sure the gaps in the rings are spaced at 120 degree spacing.Then,oil the piston,rings and bores,and just carefully place the barrel over the piston and using a small screwdriver,feed the piston ring into its groove,closing the gap,and gently applying pressure to the barrel.If you do it this way,be carefull,its easy to break a ring.Once one is in.do the next in the same way,remembering to slightly tilt the barrel to just "catch" the ring and hold it inplace while you feed it into the ring groove.The oil control ring is slightly harder,but be patient,it will go,just dont force it.    Now this is where someone tells me that the pistons are in the wrong way around:eek:

_________________

[img]http://i1207.photobucket.com/albums/bb480/alastairsmith999/dave411-5.png[/im

g]Horizontally Opposed

|

| February 26th, 2012, 11:11 am |

|

|

|

602

Firing on two.

Joined: July 21st, 2010, 7:12 pm

Posts: 859

Location: Chatenet, France

|

Re: Dave 411's 1967 AK350. Nice set of pictures Dave.

_________________

No offence is implied or intended with any of my posts. I love you all, well most of you anyway.

|

| February 26th, 2012, 11:15 am |

|

|

|

dave 411

Firing on two.

Joined: August 19th, 2010, 10:44 pm

Posts: 1815

Location: Cardiff

|

Re: Dave 411's 1967 AK350. Thanks Paul,but for some reason,the post has been posted twice

_________________

[img]http://i1207.photobucket.com/albums/bb480/alastairsmith999/dave411-5.png[/im

g]Horizontally Opposed

|

| February 26th, 2012, 11:16 am |

|

|

|

subarupete

Firing on two.

Joined: March 5th, 2009, 6:23 pm

Posts: 2251

Location: Near Monmouth

|

Re: Dave 411's 1967 AK350. Good piece of work

|

| February 26th, 2012, 11:42 am |

|

|

|

samfieldhouse

Firing on two.

Joined: February 11th, 2009, 12:32 am

Posts: 3324

Location: Chichester, West Sussex

|

Re: Dave 411's 1967 AK350.

|

| February 27th, 2012, 8:18 pm |

|

|

|

dave 411

Firing on two.

Joined: August 19th, 2010, 10:44 pm

Posts: 1815

Location: Cardiff

|

Re: Dave 411's 1967 AK350. Shit Sam,calm down,do you have a girl friend?

_________________

[img]http://i1207.photobucket.com/albums/bb480/alastairsmith999/dave411-5.png[/im

g]Horizontally Opposed

|

| February 27th, 2012, 11:01 pm |

|

|

|

dave 411

Firing on two.

Joined: August 19th, 2010, 10:44 pm

Posts: 1815

Location: Cardiff

|

Re: Dave 411's 1967 AK350. OK,time to fit the heads.A light smear of copperslip to the top of the cylinders,and a coating of sealant to the base of the cylinder and valve stem seals,   and gently push the head down onto the top of the barrell,making sure that the stem seals go into their respective holes.  Next,a good squirt of oil down the push rod tubes onto the cam followers,and a drop onto the ball ends of the push rods,the push rods go into the tubes with the big ball end first.Now the rockers and shafts,all well oiled go on.Brass washers and head nuts now,and torqued up in sequence as per the Haynes mannual.Now,in the Haynes mannual is says to torque them to 18 ft lb,and in my other mannual,whose name i have temporarly forgoten,it says 15ft lb,so i have torqued them to 17,what do we think?   So,at this point I am looking at the engine feeling good,and am just turning it over with a spanner on the crank,as you do, when I all of a sudden hear a noise that i am not happy with,a sort of clunk.After invesitgating,I found that it was happening when both pistons were at tdc.Hmm,"what could this" be or words to that effect. The first thing I did was to slacken off the rockers to take some strain off the cam etc,still there. Next,took the heads back off,just incase something had found its way into one of the cylinders.Nothing,clean as a whistle. Had a good look at everything,valves,rockers,pistons,even pulled the barrells off,but could see nothing that could cause this noise. Re- assembled everthing,after checking the rockers were the correct ones. I then spoke with Ken and Sean,who were both as baffled as me. Sean suggested trying to push down on the push rods by hand with the rockers off and the heads torqued,one at a time to see if i could "feel" a noise through them.Nothing. So,now the heads were on,now push rods fitted,so no valves opening,and the noise had gone.Must have turned the engine over 100,s of times to make sure it had gone. Hmm,could a valve be touching a piston?Heads back off,put a smear of grease on the valves,re-assembled,again,pistons clean as a whistle. Right,push rods back out,and put back one at a time.Left cylinder first,inlet valve first,the noise is there.Remove push rod,fit exhaust rod,bang now its here as well. Thats it,strip back down,split crankcases,must be something visible?Dont be daft,everything looked perfect.At this point I am stsrting to panic,only a little,but panic none the less. After cleaning off all the sealer from the crankcases and barrells etc,I decided to re-assemble,with more care than usual,and making sure everything was swimming in oil. No pics of all this as they would only be the same as the others:) Now the moment of truth,,,,,,,,its still there,but only just.More of the noise you might expect when two con rods are rocking over tdc,maybe,hopefully. I have decided to just finish rebuildiong it and see what happens:eek: Thanks to Ken and Sean,who rang me from Scotland,for their help and guidance.Sometimes,a friendly chat can work wonders

_________________

[img]http://i1207.photobucket.com/albums/bb480/alastairsmith999/dave411-5.png[/im

g]Horizontally Opposed

|

| March 4th, 2012, 10:27 am |

|

|

|

602

Firing on two.

Joined: July 21st, 2010, 7:12 pm

Posts: 859

Location: Chatenet, France

|

Re: Dave 411's 1967 AK350. Hi Dave, I believe the engine has now arrived in the UK.

_________________

No offence is implied or intended with any of my posts. I love you all, well most of you anyway.

|

| March 9th, 2012, 7:15 pm |

|

|

|

dave 411

Firing on two.

Joined: August 19th, 2010, 10:44 pm

Posts: 1815

Location: Cardiff

|

Re: Dave 411's 1967 AK350.  Thanks Paul,will arrange collection

_________________

[img]http://i1207.photobucket.com/albums/bb480/alastairsmith999/dave411-5.png[/im

g]Horizontally Opposed

|

| March 10th, 2012, 9:43 am |

|

|

Who is online |

Users browsing this forum: No registered users and 155 guests |

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot post attachments in this forum

|

|