�Long term project, Dyane4x4

| Author |

Message |

|

4x4 SuperFinn

Firing on two.

Joined: February 13th, 2009, 10:34 am

Posts: 584

Location: Franken, D

|

Re: Long term project, Dyane4x4 subarupete wrote: Enjoy the 4x4, know exactly what you mean when it pushes from the back, also you can feel the "rear" when you stuck  Ditto!

_________________

|

| November 9th, 2016, 5:03 pm |

|

|

|

jasu

Firing on two.

Joined: August 8th, 2012, 11:00 am

Posts: 480

Location: Korpilahti, Finland

|

Re: Long term project, Dyane4x4 Made a "new" fuel filler...  The filler tube is from Ami8...   Much better, now it works like it should. No spilling over, ventilation doesn't get blocked as earlier. On next summer I will make inner wing nicer, now it is too cold to think about it... Tried to make a short film about getting sideways with that, but I can't shoot and drive properly at same time. Maybe later on this winter I can make some video... Some weird grin has been seen after having some fun with...

|

| November 10th, 2016, 4:56 pm |

|

|

|

jasu

Firing on two.

Joined: August 8th, 2012, 11:00 am

Posts: 480

Location: Korpilahti, Finland

|

Re: Long term project, Dyane4x4 Changed some fuel hose...  Installed on June 2016, now it looked like that...   Maybe this last longer, tube is AISI316. Only the tube from tank to pre-filter done, also return tube bended to fit to tank, need to bend another end next but not at home lying on my park slot partly in water/oil mix... That removed hose was restricting fuel flow, so the fuel pump sounded like broken, now it has correct sound. There was also some perish on inside of that hose... No other than Gates multifuel hose is coming anymore to any of my cars, that cheap one I installed mostly because I didn't know how the hose routings should make...

|

| November 19th, 2016, 4:35 pm |

|

|

|

jasu

Firing on two.

Joined: August 8th, 2012, 11:00 am

Posts: 480

Location: Korpilahti, Finland

|

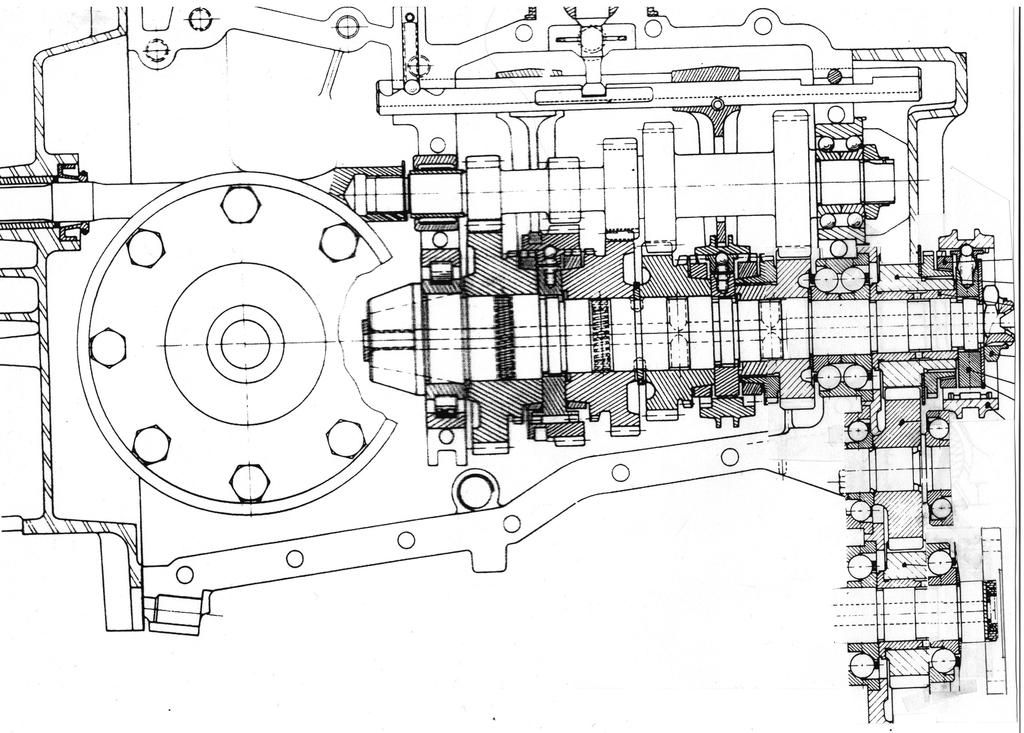

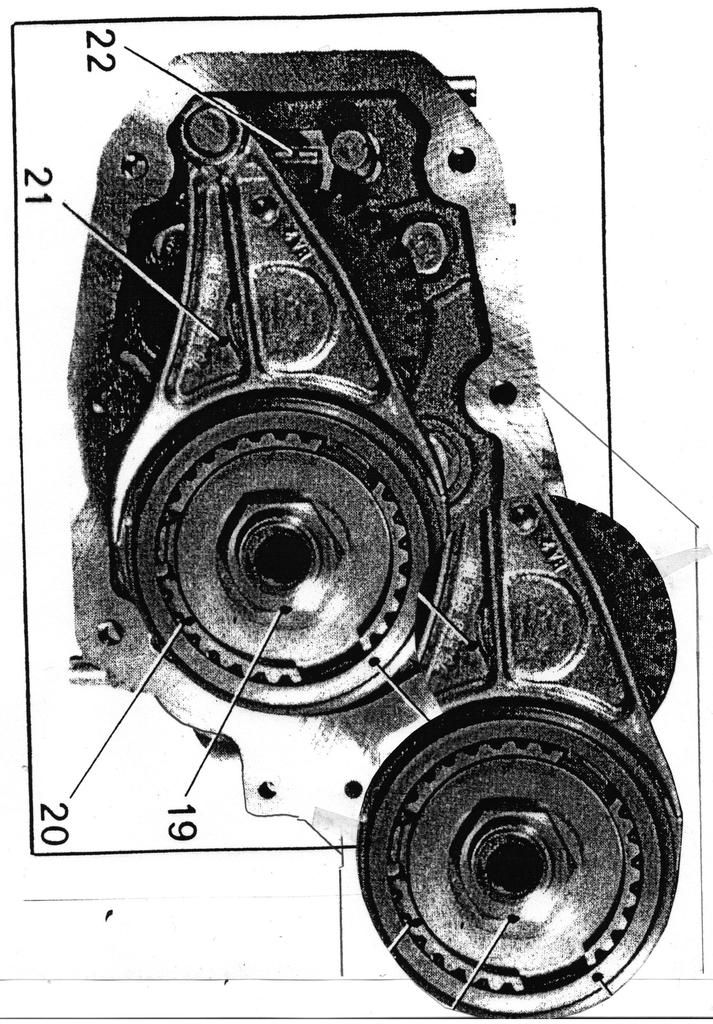

Re: Long term project, Dyane4x4   More thinking about that...  So, I looked inside of LNA, 652 Visa and GS 5-speed gearbox. Got some answers and lot of more questions. But find nothing (yet?) to stop thinking...  4th and 5th speed gears, it is possible to put 4th gear instead of 5th gear, so much easier to find gears...

|

| November 24th, 2016, 7:50 pm |

|

|

|

subarupete

Firing on two.

Joined: March 5th, 2009, 6:23 pm

Posts: 2142

Location: Near Monmouth

|

Re: Long term project, Dyane4x4 Jasu,

Do you plan to use the solution as per the gearbox drawing,

I think you only need an extra gear, the splinded 5th gear, from the top shaft.

That gives you a ratio of 1:1 thus your rear diff needs to be the same ratio as the front diff.

I may have a spare gear 5th gear, but It depends on getting some LNA gears, from a friend.

Let me know your plan.

Do know the time scale as the parts are a long way from me.

Cheers

Peter

|

| November 24th, 2016, 8:18 pm |

|

|

|

subarupete

Firing on two.

Joined: March 5th, 2009, 6:23 pm

Posts: 2142

Location: Near Monmouth

|

Re: Long term project, Dyane4x4 Amendment  Parts needed 5th gear splined 5th + syncro + dog + bush. Ps Be carefull to keep the thick washer next to the bearing, its sets the pinion height!! Cheers Peter

|

| November 24th, 2016, 8:35 pm |

|

|

|

jasu

Firing on two.

Joined: August 8th, 2012, 11:00 am

Posts: 480

Location: Korpilahti, Finland

|

Re: Long term project, Dyane4x4 I try if I can use two 4th gears and a gear between them from mainshaft. On LNA and Visa is same 4th gear ratio, differs from any GS box. And if there is more space needed between pinion shaft and output shaft, it seems to have same pitch on 3rd and 4th gears... Need to machine the mainshaft shorter, and also to fit another bearing. So there will be 1:1 ratio on dropped output shaft... And a while ago, friend just called I can have an output shaft and propshaft flange from Land Rover LT230 transfer box. Again, little overkill, but the price matters (free)...  From memory, on that L-R shaft is splined part, what has larger diameter than 4th gear hole is, they are possible to mate together. But I'm sure when I have those parts... Have been thinking that a lot on last days. Making steel plates could be hard to do with onlydrill and angle grinder, so yesterday when I was getting some steel I asked the price of about 200x400x8mm plate with laser-cutted holes, I was very surprised to hear they should cost less than 25€ piece...

|

| November 24th, 2016, 8:45 pm |

|

|

|

jasu

Firing on two.

Joined: August 8th, 2012, 11:00 am

Posts: 480

Location: Korpilahti, Finland

|

Re: Long term project, Dyane4x4 subarupete wrote: Ps Be carefull to keep the thick washer next to the bearing, its sets the pinion height!! Yes. Have learned that, same on 2cv box. But much easier to measure the needed thickness on 2cv box... I can't mix those parts on LNA and Visa box, those have 0,5mm difference on end of the shaft, also on that washer and bearing too..! Next is to measure also that dimension on GS bearings. Had to get home too soon today, couldn't measure them yet...

|

| November 24th, 2016, 8:50 pm |

|

|

|

subarupete

Firing on two.

Joined: March 5th, 2009, 6:23 pm

Posts: 2142

Location: Near Monmouth

|

Re: Long term project, Dyane4x4 Laser cutting is very good value, Here the local company has a minimum order of €100  Using steel is ok but the back of a GS box is 25mm to support the bearings, so the extra plate to carry the new bearings needs to be 20/25mm. With steel that wil be heavy.

|

| November 25th, 2016, 10:34 am |

|

|

|

jasu

Firing on two.

Joined: August 8th, 2012, 11:00 am

Posts: 480

Location: Korpilahti, Finland

|

Re: Long term project, Dyane4x4 subarupete wrote: Using steel is ok but the back of a GS box is 25mm to support the bearings, so the extra plate to carry the new bearings needs to be 20/25mm. With steel that wil be heavy. I have plan on my mind, to use same thickness (8mm?) as is 5-speed plate, and make bearing housing from aluminium. Many of these "small details" will be solved at some time. And many of them can't see on photos, need to play with real parts, you know...

|

| November 25th, 2016, 10:54 am |

|

|

Who is online |

Users browsing this forum: No registered users and 19 guests |

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot post attachments in this forum

|

|