Fuel filler done...

| International2cvFriends.com http://www.international2cvfriends.com/forum/ |

|

| �Long term project, Dyane4x4 http://www.international2cvfriends.com/forum/viewtopic.php?f=19&t=5823 |

Page 4 of 16 |

| Author: | jasu [ July 27th, 2016, 8:55 pm ] |

| Post subject: | Re: Long term project, Dyane4x4 |

Fuel filler done...

|

|

| Author: | subarupete [ July 28th, 2016, 4:13 pm ] |

| Post subject: | Re: Long term project, Dyane4x4 |

Is the plan to make the car a "sleeper"? |

|

| Author: | subarupete [ July 28th, 2016, 4:17 pm ] |

| Post subject: | Re: Long term project, Dyane4x4 |

I see you have used "silcone" hose on the fuel filler. Is that OK with Ethanol, thats now in some petrol? |

|

| Author: | jasu [ July 28th, 2016, 8:30 pm ] |

| Post subject: | Re: Long term project, Dyane4x4 |

I have used silicone hose earlier, on my other Dyane. And it isn't melted or leaked a single drop... Hope that hose don't start leaking, but I'm very sure it will work... But who knows after 50 year..? And answer to the other question, yes. As original as could be, no plan to wash, and some winter fun with supercharged 4x4, some surprices might happen with othes drivers, that's the plan... |

|

| Author: | jasu [ August 14th, 2016, 8:59 pm ] |

| Post subject: | Re: Long term project, Dyane4x4 |

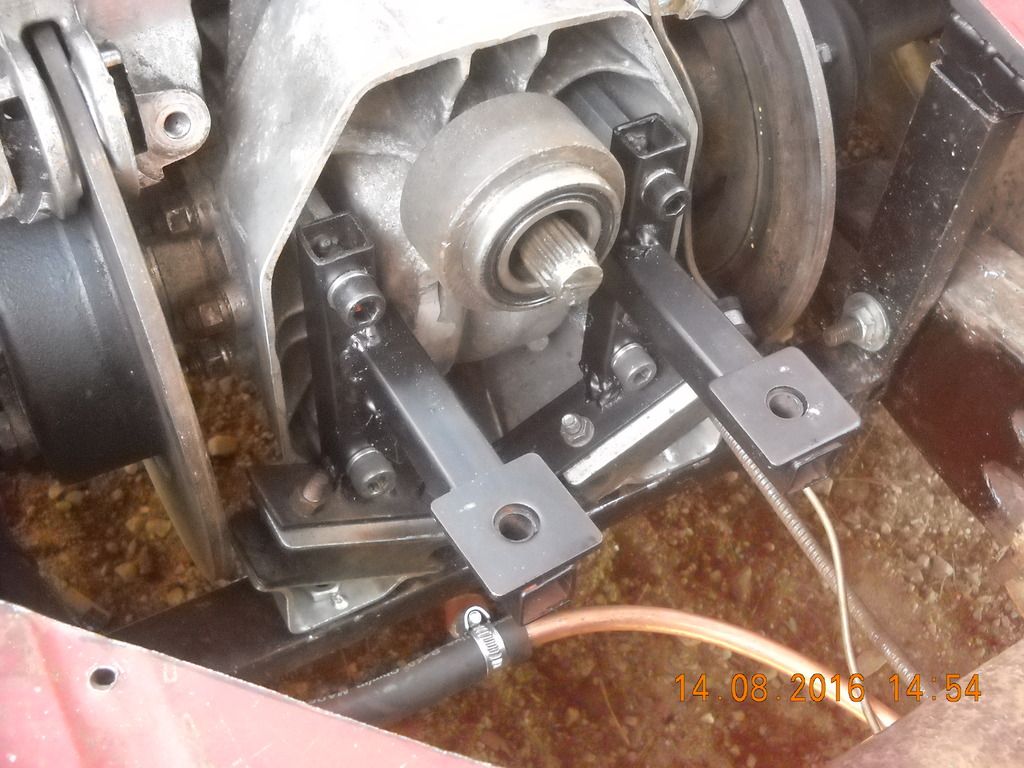

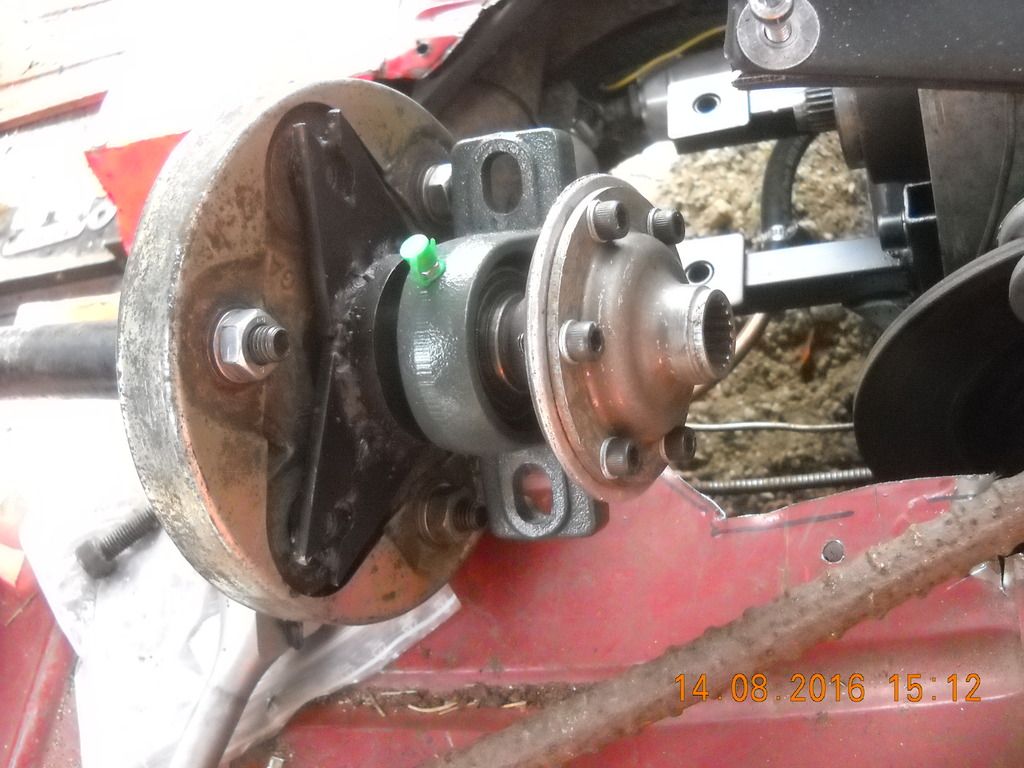

Made new parts to rear diff and propshaft coupling..:    That bearing just forgot to remove, it has too big inner diameter and will be changed to correct size what I didn't have at garage...        And yes, it didn't broke when tested without front wheels and front end supported by wooden blocks. Had playing with clutch for some time engine RPM between 2-3000RPM and the car wanted to go forward with only rear wheels on gravel. Tires are quite worn, but still it was very surprising to see how well it tried to go on... And the other surprising moment was to see how much rear diff moves at max torque at that situation, several cm uward at front end, but not too much I think... The technical inspection is closer now, not much to work for that. License plates are ordered and waiting to pass that inspection... |

|

| Author: | subarupete [ August 14th, 2016, 11:06 pm ] |

| Post subject: | Re: Long term project, Dyane4x4 |

Have you done this to your gearbox mounts. viewtopic.php?f=19&t=3279&hilit=Engine+mount&start=110 |

|

| Author: | jasu [ August 15th, 2016, 6:49 am ] |

| Post subject: | Re: Long term project, Dyane4x4 |

Not (yet), didn't remember those at all... Those are easy to remove and modify. They are quite must to make..? Thanks |

|

| Author: | jasu [ August 18th, 2016, 5:57 pm ] |

| Post subject: | Re: Long term project, Dyane4x4 |

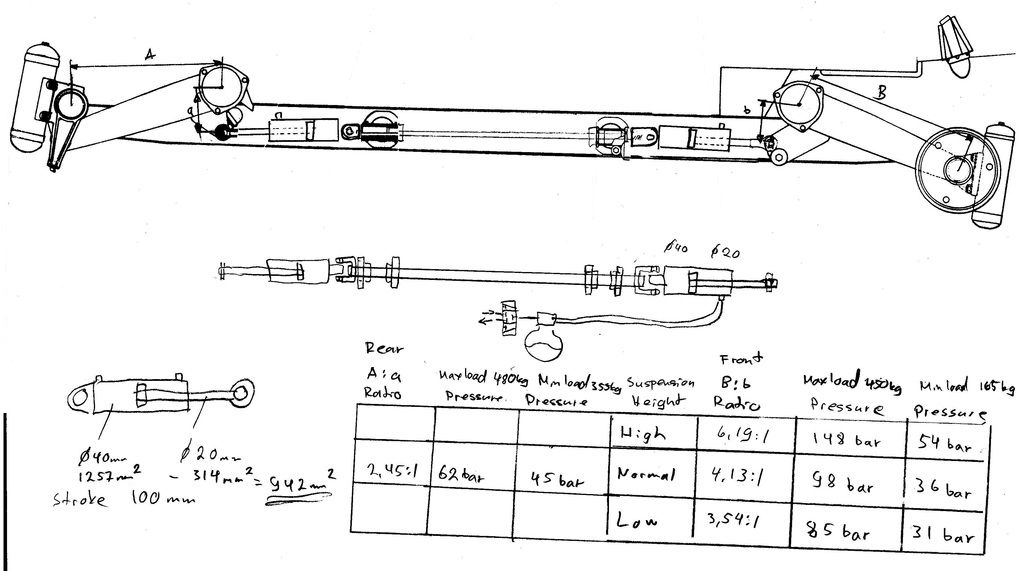

Couldn't get to garage for a while, but head is all the time thinking something. Nice to wake up in the middle of the night with clear vision, then at daylight some calculations etc, hope to have this constructed at some year...  Standard hydraulic cylinders with 40mm bore, 20mm rod diameter and 100mm stroke. About 90€ piece.  Connected to Cx/Xm brake accu (that little green part, DS/SM has that unit integrated to sphere), with removed check valve, height controlling by electrics. Rear anti-roll bar is easy to install inside rear axle tube, and if used separate valves for both front wheels there isn't need to anti-roll bar at front... Also it can be enough if used Hydractive center sphere unit without sphere, it practically isolates the cylinders... If damper valve isn't enough at suspension spheres, there is still change to use original hydraulic shocks. They just need to test, what damper valve is good, or use old serviceable spheres from D-series what have rebuildable valves. Filling those isn't problem because we made tools for that some years ago... |

|

| Author: | subarupete [ August 18th, 2016, 7:41 pm ] |

| Post subject: | Re: Long term project, Dyane4x4 |

Like it alot.... Are the front and rear connected? |

|

| Author: | jasu [ August 18th, 2016, 8:16 pm ] |

| Post subject: | Re: Long term project, Dyane4x4 |

subarupete wrote: Are the front and rear connected? Hydraulics separated as front and rear, with own height correctors, as is been from -55. I was thinking it could be good to mount both cylinders to common bar and lock that to spring pot mounting points. So the biggest stress isn't to mountings, but the cylinders itself. Also installing would be easy... Direct replacement for spring pots? If this design works, I think someone else could be very interested about. Also put this here, and hope if someone find something what is total wrong says that... EDIT: Oh, there is a mistake on calculations, the pressure figures aren't right. Also on these calculations is unspring mass with what should be removed. I'll correct them tomorrow EDIT: Calculations corrected, and photo changed to Photobucket... |

|

| Page 4 of 16 | All times are UTC + 1 hour [ DST ] |

| Powered by phpBB © 2000, 2002, 2005, 2007 phpBB Group http://www.phpbb.com/ |

|